Rotor Dynamics

Turbine Shutdown Procedures

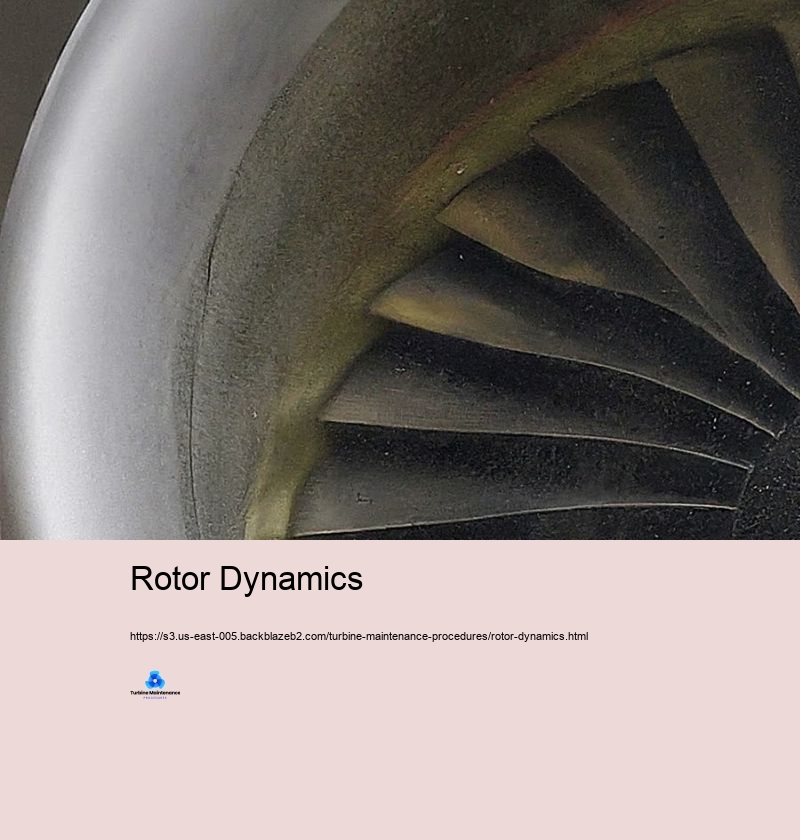

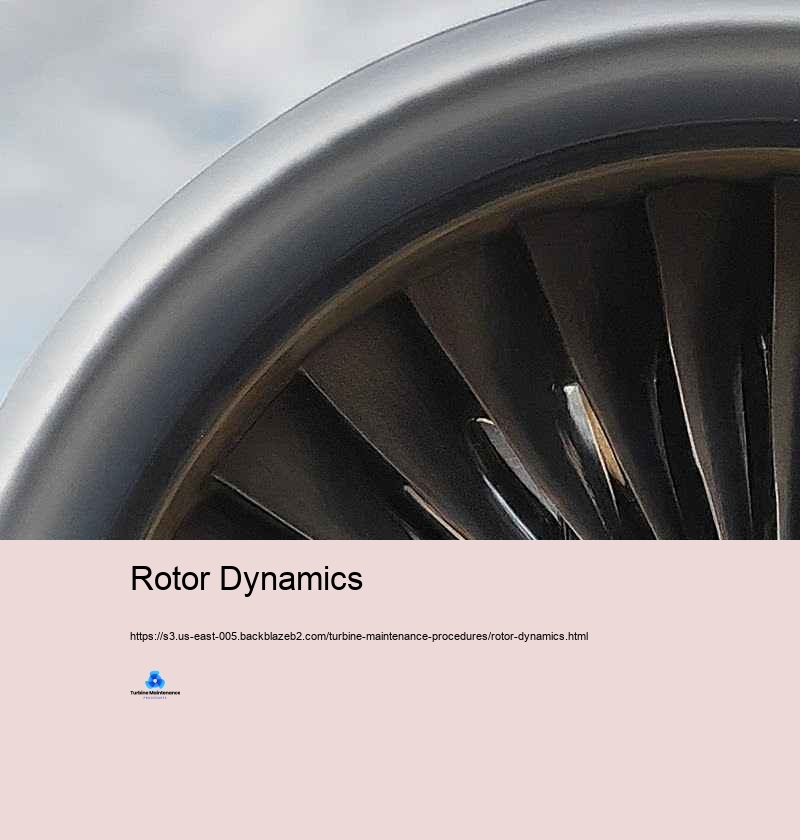

Turbine maintenance is a crucial aspect of power generation, commercial procedures, and different various other applications where generators play an important duty. Correct maintenance ensures perfect efficiency, expands the lifespan of the devices, and quits costly break downs. This intro to turbine maintenance checks out the important principles and practices essential for maintaining these complex makers properly. At its core, turbine maintenance pertains to maintaining the honesty and effectiveness of the turbine system. Turbines, whether hefty vapor, gas, or hydraulic, are sophisticated pieces of equipment that transform power from a fluid (hefty steam, gas, or water) right into power. The high-speed turning, severe temperature levels, and anxiety involved in their treatment make typical and complete maintenance important. One of the fundamental concepts in turbine maintenance is preventive maintenance. This aggressive approach consists of routinely set up assessments, cleaning, and minor fixing solutions to stop major failings before they take place. Preventive maintenance normally includes jobs such as lubricating bearings, examining and changing clearances, evaluating blades for wear or damages, and examining vibration levels. By dealing with little problems early, preventive maintenance can substantially reduce the risk of devastating failings and lengthen the turbine's practical life. Condition-based maintenance is an extra key idea that has acquired reputation with the introduction of sophisticated security technologies. This approach relies on real-time data from sensing units and monitoring systems to determine when maintenance is required. Rotor Dynamics Standards such as resonance, temperature level, pressure, and oil problem are continuously kept an eye on. When these criteria differ regular selections, it shows potential concerns that call for emphasis. Condition-based maintenance permits a lot more targeted and efficient maintenance tasks, decreasing unnecessary downtime and optimizing source allocation. Predictive maintenance takes condition-based maintenance a step much more by using information analytics and artificial intelligence formulas to anticipate when failures are likely to take place. By checking out historic data and existing operating problems, predictive maintenance systems can prepare for possible problems before they appear as noticeable issues. This strategy authorizations maintenance groups to prepare treatments at one of the most suitable times, lowering disruption to operations and making the most of the efficiency of maintenance activities. Alignment is a crucial technique in turbine maintenance. Proper positioning of the turbine shaft with the generator or driven tools is necessary for smooth procedure and long life. Discrepancy can cause extreme resonance, increased wear of bearings and seals, and decreased performance. Regular placing checks and changes, frequently making use of laser positioning devices, are a conventional component of turbine maintenance routines. Integrating is one more crucial element of turbine maintenance. The high-speed rotation of turbine parts indicates that even little discrepancies can reason considerable resonance and wear. Dynamic harmonizing of blades and impellers is carried out to make certain smooth treatment. This procedure involves adding or eliminating small amounts of weight at information suggest achieve maximum balance. Typical vibration analysis helps figure out inequality issues early, enabling timely modifications. Assessment and cleansing of turbine blades are crucial maintenance practices. Blades can deal with various issues such as erosion, rust, fouling, or physical damage. Regular evaluations, normally making use of borescopes or numerous other non-destructive testing strategies, aid determine these problems. Cleaning up of blades, which could include chemical cleaning up or mechanical techniques like grit blasting, help preserve wind immune effectiveness and avoids effectiveness destruction. Lubrication administration is a critical element of turbine maintenance. Proper lubrication of bearings, gears, and other relocating components is crucial for decreasing rubbing and put on. This entails not just making certain an adequate supply of lube yet additionally inspecting its high quality. Oil evaluation is a common method that aids locate pollutants, wear pieces, and modifications in oil homes that may recommend creating problems in the turbine system. Seal maintenance is one more crucial strategy. Seals protect versus leak of operating fluids and lubricating substances, and their failure can bring about considerable performance losses and prospective protection dangers. Routine assessment and alternative of seals, specifically in high-pressure or high-temperature areas, is a common component of turbine maintenance routines. Control system maintenance is progressively important as wind turbines come to be a lot more automatic and electronically taken care of. This includes routine checks and calibration of sensing units, actuators, and control shutoffs. Software application updates and cybersecurity activities are additionally essential facets of contemporary turbine control system maintenance. Safety and security is very vital in all turbine maintenance tasks. Generators require high powers, severe temperature level levels, and potentially dangerous products. Strenuous adherence to protection procedures, including lockout/tagout procedures, constrained area gain access to procedures, and proper use individual safety tools (PPE), is vital.

Rotor Dynamics - Condition Monitoring Systems

- Inspection Checklists

- Maintenance Scheduling

- Turbine Overhauling Procedures

- Component Replacement

- Oil Analysis

- Seal Inspections

- Heat Exchanger Cleaning